Our Approach to Community

Beyond the broad economic benefits that our operations provide, Arch and its subsidiaries make it a priority to enrich our local communities in other ways, too. We encourage our employees to take an active role in community organizations and projects, and to cultivate strong relationships with neighbors.

Through philanthropic and economic contributions, we believe we are improving the quality of life in the areas in which we operate — for the benefit of our own employees and their families as well as the broader communities in which they live and work.

Arch and its operating subsidiaries have made open communication and dialogue a high priority. We use various tools and forums to promote community engagement, including community advisory panels (CAPs). At the Leer metallurgical mine in Grafton, West Virginia, for example, the mine’s leadership team meets quarterly with a CAP comprised of approximately 20 representatives from the area, including business leaders, educators, emergency responders, and elected officials, among others. During these meetings, the mine informs community leaders about upcoming mine developments of significance, including its future investment and development plans, and educates these community leaders on the process of mining. At the same time, the meetings create opportunities for community members to ask questions, share concerns, and make suggestions about opportunities for collaboration between the mine and the local citizenry.

The success of the Leer CAP inspired the company to establish a second community advisory panel in Philippi, West Virginia, where an Arch subsidiary recently completed construction of a second world-class metallurgical mine called Leer South. By engaging community members at the earliest stages of the mine’s development, the Leer South team was able to solicit valuable input about its neighbors’ needs, aspirations and concerns. Based on this feedback, the mine made a commitment to fund needed upgrades to Adaland Mansion, a cultural center, event site and tourism attraction located in Philippi that is listed on the National Register of Historic Places.

Arch and its subsidiaries undertake a formal process for stakeholder engagement and consultation in advance of the opening of any new operation, and maintain that engagement on a continuing basis at existing operations. While the forum for such engagement varies from mine to mine — with the CAPs at our Leer and Leer South operations being but two examples of our formal outreach efforts — every subsidiary operation engages frequently and continuously throughout the year with area residents, local businesses, landowners, government agencies and other officials, Tribal Nations if and as applicable, and other relevant stakeholders.

Before the development of a new mine commences or mining activities begin — as well as at key points during the mining process — Arch subsidiaries engage with multiple federal and state agencies to secure the necessary permits to conduct business. Public comment opportunities are a central component of these efforts, and Arch takes its obligations to community engagement and outreach seriously. Our goal is to be as responsive as possible to community concerns, and to work with neighbors and community leaders to address and allay concerns to the fullest extent possible.

Exemplifying this commitment to public involvement, both Leer and Leer South have been honored in recent years with the U.S. Department of Interior’s Good Neighbor Award — the nation’s highest honor for community engagement and outreach — for their efforts to engage with and support their communities as well as to advance critical infrastructure projects.

That spirit of support extends across the broader region as well. During 2022, the Leer mine loaded four U-Hauls with relief supplies for victims of severe flooding in communities in the neighboring state of Kentucky.

During 2022, the Leer South mine conducted a large-scale mock disaster exercise as part of its emergency warning and crisis management readiness efforts. The drill created an invaluable opportunity for local first responders, regulatory agencies, community partners and mine personnel to identify, understand, and practice roles and responsibilities critical to successful crisis management. A total of 16 agencies and more than 65 individuals participated in the drill, with many of those same people participating in a subsequent debrief on the key learnings associated with the activity. The Barbour County Commission recognized the mine’s efforts with an exemplary community service award.

As another example of Arch’s strong commitment to serving community interests, subsidiary operations have designed and installed new mine ventilation fans with advanced noise-dampening technologies. As a result of this incremental investment, the new ventilation fans are roughly 1/20th as loud as typical mine ventilation fans.

Funding Projects that Benefit Communities

Number of additional homes receiving city sewer services because of a $2 million, threemile sewer line extension funded in part by Leer South

The Leer South mine recently engaged with the City of Philippi and the federal Economic Development Authority to help fund a $2 million, three-mile sewer line extension that will serve the needs of the mine while facilitating the extension of city sewer services to as many as 150 additional homes.

Similarly, the Mountain Laurel mine worked with a group of community leaders — providing both equipment and labor — to develop Rockhouse Lake, a recreational facility and natural resource located in a 127-acre park. The lake and park provide significant outdoor opportunities in Logan County, West Virginia. Employees have also donated their time and resources to continue to enhance the offerings at the lake, including improving accessibility. In recent years, employees have volunteered their time to work with local residents with disabilities, helping them to take advantage of the new, accessible facilities. Mountain Laurel has also provided grounds maintenance services at the facility to ensure access to the lake’s walking paths, boat docks, and fishing benches, and — in 2022 — hosted a Children’s Fishing Day.

In another effort, the Leer mine partnered with the Taylor County Soccer Association in Knottsville, West Virginia, to provide land for the development of a nonprofit soccer complex that provides thousands of area families a place to play, exercise and practice healthy lifestyles.

Arch’s subsidiaries have made education and partnering with local schools a particular emphasis for the long-term health and success of their communities.

Arch’s subsidiaries have made education and partnering with local schools a particular emphasis, which they believe is a sound investment not only in their own future workforces, but also in the long-term health and success of their communities. Arch subsidiary employees support and participate in a wide array of activities, including high school career days, Earth Day events, veterans’ organizations, “read-to-me” days, field trips, Adopt-a-Highway programs, women’s resource centers, science and social studies fairs, long-term care facilities, Hospice organizations, and many other efforts.

Mountain Laurel hosted its annual Earth Day celebration in 2022, with two local schools and more than 80 students and school staff participating. Students learned about beekeeping and the essential role bees play in the natural environment, and enjoyed a hands-on experience related to the collection of aquatic insects and crustaceans as a way to gauge the health of streams and promote water quality compliance, among other activities.

During 2022, Leer South hosted more than 80 area middle school students as part of a STEAM exposition, with the theme of “Reduce, Reuse, Recycle.” During 2022, the Leer mine’s giving fund donated backpacks full of school supplies to 525 elementary and pre-K students at a nearby elementary school.

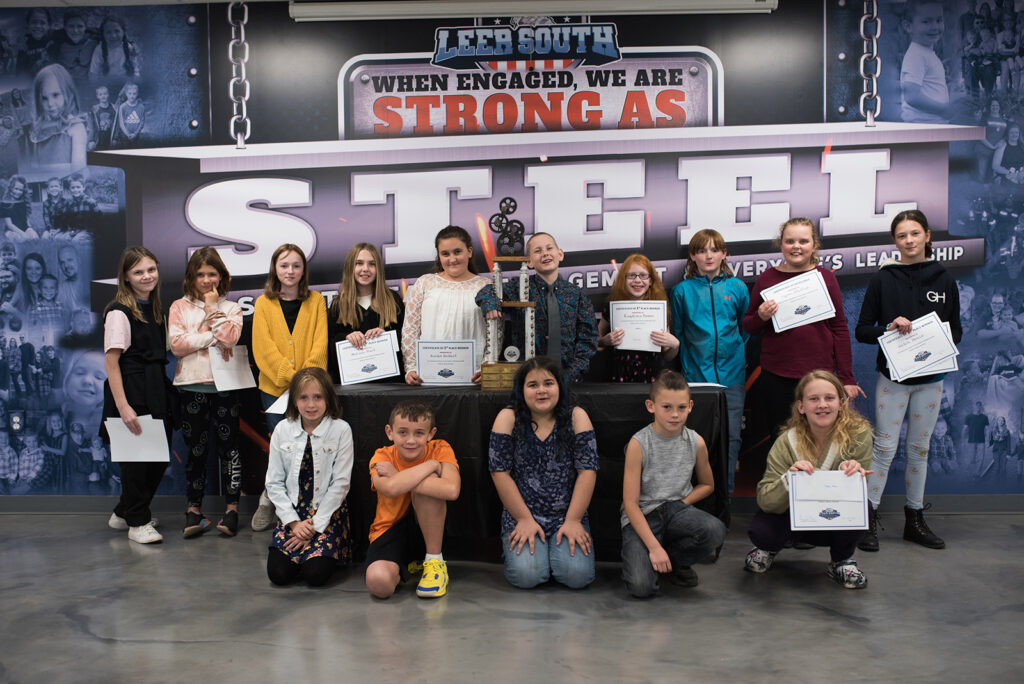

Arch’s subsidiary operations make it a priority to support their local school systems, which translates into an investment in their future workforces. This photo shows award winners from the recent STEAM Expo at Leer South.

Arch subsidiaries also collaborate with — and provide support to — a broad array of conservation and outdoor organizations, which is an excellent complement to Arch’s strong commitment to environmental stewardship. For instance, Arch operations partner with the National Wild Turkey Federation to support youth hunts, fishing days, recognition events, and other activities, and work with the Rocky Mountain Elk Foundation to support habitat enhancement and elk management activities.

During 2022, Arch’s Powder River Basin subsidiary — as part of an ongoing partnership with the U.S. Forest Service — focused its attentions on improving local recreational areas, which included the cleanup of a dump site in the Thunder Basin National Grasslands (TBNG); the addition of a floating dock, signage, an access path and facilities at the East Iron Creek Reservoir; and continuing support for the TBNG Sage Grouse Core Habitat Restoration Project.

In addition to these activities, Arch operations sponsor and support a host of other significant causes each year, including drug abuse prevention efforts, blood drives, health-related community events such as Relay for Life, and numerous other efforts.

In total, Arch and its subsidiaries have contributed nearly $2.7 million to charitable organizations and causes over the course of the past five years.

The employees of the corporation and its operating subsidiaries have a political action committee that helps amplify their collective voice on political matters of interest and concern. In addition, the organization engages and lobbies elected and public officials on issues of importance to the company, its operating subsidiaries and employees throughout those organizations.

Information on the company’s political action committee can be found here: https://www.fec.gov/data/committee/C00167668/. Information on the company’s lobbying activities can be found here: LD-2 Disclosure Form (house.gov). In addition, the company and its subsidiaries participate in a number of trade associations that engage in political outreach and advocacy, including the National Mining Association, the West Virginia Coal Association, the Wyoming Mining Association and the Colorado Mining Association.